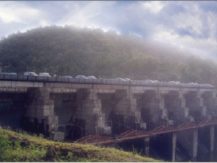

Spillway piers showing leakages

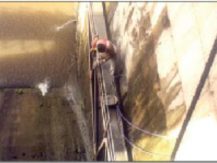

Leakages at constriction joints

Tracing the path of leakage and diverting the same through PVC ports

Grouting the ports with Cementatious grout with varying water/cement ratios. (Grouting was done with natural pressure, not by pumps)

Pier after completion of grouting

Make OR Break Factor

All investigative and construction work had to be carried out at full reservoir levels.

THE CHALLENGE :

- The dam was witnessing water leakages through its RCC piers, that was affecting its performance and endangering the whole structure.

THE ODDS :

- Given the nature of the structure, the solution had to be designed keeping in mind the cohesiveness of application as well as local material available on the site.

OUR RESPONSE :

- Our first step was to Investigate the extent and path of the various leakages

- After which, we designed a system that utilized local material available at the site and executed the process