Damaged RCC beam and slab

Beam after replacement of bottom cover portion

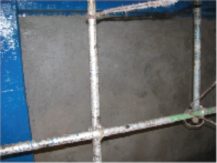

Slab and beam after completion of patch repair

Drilling on slab for grouting

Structure after completion of repair

Make OR Break Factor

Because of severe space constraints, conventional systems could not be adapted, and improvisations had to be made.

THE CHALLENGE :

- All RCC members had been exposed to a fire explosion and were suffering considerable local damage thus compromising safety of the staff as well as posing an environmental threat.

THE ODDS :

- All work had to be completed within the 20-day shutdown period.

OUR RESPONSE :

- Initially, the damage was evaluated and the existing design was assessed, on the basis of which a retrofit method was provided

- We grouted the damaged core sections of concrete while patch repaired the damaged concrete sections and reinforced some of the structural members with fibre-wrapping system